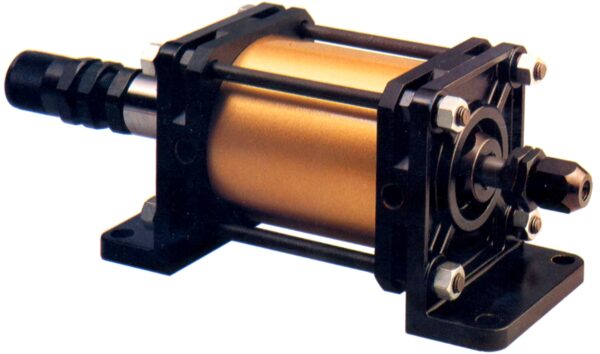

Percussion Press – Integrator

$5,565.00 – $14,437.50

Integrator Presses are compact and versatile, and the ideal solution for fitting into automated production lines and machines. The flange mounting design has the benefit of a removable hand lever for manual operation, if required, plus the air cylinder to actuate the ram.

- Pneumatically Operated Impact Press via a foot switch (supplied)

- The ram design consists of a co-axial module and provides the maximum power in the smallest space.

- The unit can be mounted in any direction using the four mounting holes.

- Securely fix to a supporting structure in relation to the item to be marked.

- Product Information

- Safety Information

- Indent marking pressure

Product Information

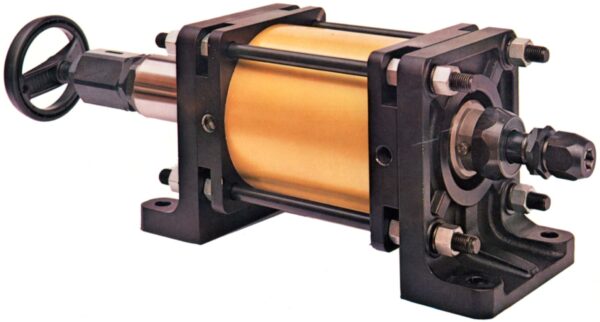

Increase Operator Safety

A Pryor Manual Percussion Press is ideal for medium output and helps to reduce the worker exhaustion that can be associated with hand and hammer marking tools and their operation. Presses are easy and safe to use on either regular or irregular workpieces. Bench-mounted presses have a large T-slotted worktable to enable easy fitting of work holding fixtures

Manual Percussion Press Information

| Marking Capacity | 0 – 600Kg | 0 – 3500 Kg | 0 – 7500Kg |

| Weight | 2Kg | 10Kg | 38Kg |

| Air Pressure | 4 bars | 6 bars | 6 bars |

| Air Consumption | 0.5L | 2.3L | 5.4L |

| Shank | HMS080 8mm dia. x 32mm | HMS100 10mm dia. x 40mm | HMS160 16mm dia. x 50mm |

| Rack Stroke Length | 32mm | 67mm | 110mm |

| Tool Support Stroke Length | 8mm | 18mm | 25mm |

| Usable Stroke length | 24mm | 49mm | 85mm |

Safety Information

Please note, An Integrator Impact Press is supplied unguarded and it is the responsibility of the end user to supply and fit guarding to conform to the Health & Safety At Work Act. However, we will need a Letter of Intent stating that guarding will be fitted by the end user to conform to the act before we can release pneumatics from our factory.

During installation, the operator must ensure the unit is not subjected to vibration or movement.

Indent marking pressure

Important note:

This information relates to indent marking using engraved tooling. Marking pressures and indenting depths mostly depend upon the substrate hardness; these figures the substrate is assumed to be a typical mild steel.

Calculation:

200 Kg is required for each millimetre of character height, in order to mark mild steel to a depth of 0.1 mm. Eg a single 1 mm character requires 200 Kg. A single 2mm character requires 400 Kg. Five 3mm characters requires 3000 Kg.

| Quantity of character | ||||||||||||

| Character Height (mm) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 1.0 | 200 | 400 | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 |

| 1.5 | 300 | 600 | 900 | 1200 | 1500 | 1800 | 2100 | 2400 | 2700 | 3000 | 3300 | 3600 |

| 2.0 | 400 | 800 | 1200 | 1600 | 2000 | 2400 | 2800 | 3200 | 3600 | 4000 | 4400 | 4800 |

| 2.5 | 500 | 1000 | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 5500 | 6000 |

| 3.0 | 600 | 1200 | 1800 | 2400 | 3000 | 3600 | 4200 | 4800 | 5400 | 6000 | 6600 | 7200 |

| 4.0 | 800 | 1600 | 2400 | 3200 | 4000 | 4800 | 5600 | 6400 | 7200 | 8000 | 8800 | 9600 |

| 5.0 | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 | 11000 | 12000 |

| 6.0 | 1200 | 2400 | 3600 | 4800 | 6000 | 7200 | 8400 | 9600 | 10800 | 12000 | 13200 | 14400 |

| 8.0 | 1600 | 3200 | 4800 | 6400 | 8000 | 9600 | 11200 | 12800 | 14400 | 16000 | 17600 | 19200 |

| 10.0 | 2000 | 4000 | 6000 | 8000 | 10000 | 12000 | 14000 | 16000 | 18000 | 20000 | 22000 | 24000 |

| 12.5 | 2500 | 5000 | 7500 | 10000 | 12500 | 15000 | 17500 | 20000 | 22500 | 25000 | 27500 | 30000 |